| | Picture | Title | Category | Assembly |

|---|

|

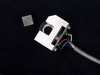

C) Wiggler.. bushing pressed in

|

C) Wiggler.. bushing pressed in |

instrument assembly |

fiber wiggler

|

|

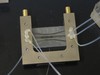

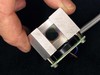

A) Wiggler.. pieces to assemble

|

A) Wiggler.. pieces to assemble |

instrument assembly |

fiber wiggler

|

|

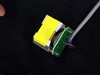

B) Wiggler.. press bushing into base

|

B) Wiggler.. press bushing into base |

instrument assembly |

fiber wiggler

|

|

D) Wiggler.. mandrel to guide Piezo Tube

|

D) Wiggler.. mandrel to guide Piezo Tube |

instrument assembly |

fiber wiggler

|

|

E) Wiggler.. Piezo Tube arranged on mandrel with stop tube

|

E) Wiggler.. Piezo Tube arranged on mandrel with stop tube |

instrument assembly |

fiber wiggler

|

|

F) Wiggler.. Ball and Ball-Mandrel and pusher

|

F) Wiggler.. Ball and Ball-Mandrel and pusher |

instrument assembly |

fiber wiggler

|

|

G) Wiggler.. Ball arranged on mandrel

|

G) Wiggler.. Ball arranged on mandrel |

instrument assembly |

fiber wiggler

|

|

H) Wiggler.. push ball down to proper level

|

H) Wiggler.. push ball down to proper level |

instrument assembly |

fiber wiggler

|

|

I) Wiggler.. Align Tube-End-Cap with drill bit

|

I) Wiggler.. Align Tube-End-Cap with drill bit |

instrument assembly |

fiber wiggler

|

|

J) Wiggler.. Tube-End-Cap pressed into place

|

J) Wiggler.. Tube-End-Cap pressed into place |

instrument assembly |

fiber wiggler

|

|

K) Wiggler.. Anti-Twist piezo pushers

|

K) Wiggler.. Anti-Twist piezo pushers |

instrument assembly |

fiber wiggler

|

|

Laser engraver

|

Laser engraver |

Tools |

Laser Engraver

|

|

(1) ADC board on first layer

|

(1) ADC board on first layer |

boards |

Controller Board Stack

|

|

(2) ADC board on second layer

The same set of 3 boards as on thye first layer (ADC board and 2 preamplifier boards) except rotated 180 degrees. |

(2) ADC board on second layer |

boards |

Controller Board Stack

|

|

(3) Motor control board on third layer

|

(3) Motor control board on third layer |

boards |

Controller Board Stack

|

|

(4) Piezo control board on fourth layer

|

(4) Piezo control board on fourth layer |

boards |

Controller Board Stack

|

|

(5) Main control board on the fifth layer

|

(5) Main control board on the fifth layer |

boards |

Controller Board Stack

|

|

(6) Connect boards with ribbon cable

|

(6) Connect boards with ribbon cable |

boards |

Controller Board Stack

|

|

(8) Color code

Green = Force detector trap-A

Blue = Position detector trap-A |

(8) Color code |

boards |

Controller Board Stack

|

|

(9) more Color Codes

Yellow = Force detector trap-B

Red = Position detector trap-B |

(9) more Color Codes |

boards |

Controller Board Stack

|

|

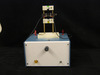

Raster Tester Light Source back

|

Raster Tester Light Source back |

Tools |

Raster test light source

|

|

Raster Tester Light Source front

|

Raster Tester Light Source front |

Tools |

Raster test light source

|

|

Controller Power Supply inside view

|

Controller Power Supply inside view |

instrument assembly |

Controller Power Supply

|

|

Power connector, 3-wire

Black is ground; red is +5V; white is +12V. |

Power connector, 3-wire |

boards |

Controller Power Supply

|

|

Power connector, 4-wire

Brown is ground; orange is +15V; blue is -15V. The reason for 4 wires is to reduce confusion with connections if both were 3-wire. |

Power connector, 4-wire |

boards |

Controller Power Supply

|

|

Controller Power Supply

|

Controller Power Supply |

instrument assembly |

Controller Power Supply

|

|

miniTweezers controller

|

miniTweezers controller |

instrument assembly |

Controller Power Supply

|

|

Blue LED light source

|

Blue LED light source |

instrument assembly |

LED light souce

|

|

Sound-proof box

|

Sound-proof box |

Tools |

Soundproof Box

|

|

Sound-proof box

|

Sound-proof box |

Tools |

Soundproof Box

|

|

micro fluidics chamber and holder

fluidics chamber mounted in holder and connected to external tubes |

micro fluidics chamber and holder |

Fluidics |

chamber holder

|

|

parts for Z-limit sensor

|

parts for Z-limit sensor |

instrument assembly |

Z-Limit Sensor

|

|

final mirror assembly

Glue mirrors with superglue |

final mirror assembly |

instrument assembly |

position detector adjustment mirror

|

|

Piezo cable harness

6 feet of 16-cond. cable, using 8 wires for 4 piezos (2 x-y pairs), and 8 unassigned.

Conductors 1-4 go to trapA wiggler on CCD side.

Conductors 5-8 go to trapB wiggler. |

Piezo cable harness |

instrument assembly |

piezo cable harness

|

|

Micro fluidic chamber

|

Micro fluidic chamber |

Fluidics |

Micro-chamber

|

|

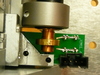

Piezo control board

version 9 uses surface-mount amplifiers Apex PA340 |

Piezo control board |

boards |

Piezo driver board

|

|

Piezo_Driver 8

version 8 used Apex PA240 amplifiers |

Piezo_Driver 8 |

boards |

Piezo driver board

|

|

miniTweezers Instrument

|

miniTweezers Instrument |

instrument assembly |

miniTweezers instrument

|

|

(A) Newport 561D-XYZ

Right-handed Newport 561-XYZ stage shown here. The left-handed version will not work in miniTweezers |

(A) Newport 561D-XYZ |

instrument assembly |

Motorized stage

|

|

(B) unscrew the rail

use hex key to unscrew rail. Always handle stage gently. Do not drop stage onto table or it will dent the rollers. Do not apply excessive force or torque to rollers while unscrewing factory parts or adding machined parts. |

(B) unscrew the rail |

instrument assembly |

Motorized stage

|

|

(C) remove platform

Always handle stage gently. Do not drop stage onto table or it will dent the rollers. Do not apply excessive force or torque to rollers while unscrewing factory parts or adding machined parts. |

(C) remove platform |

instrument assembly |

Motorized stage

|

|

(D) remove micrometer mounts

Always handle stage gently. Do not drop stage onto table or it will dent the rollers. Do not apply excessive force or torque to rollers while unscrewing factory parts or adding machined parts. |

(D) remove micrometer mounts |

instrument assembly |

Motorized stage

|

|

(E) remove base

Always handle stage gently. Do not drop stage onto table or it will dent the rollers. Do not apply excessive force or torque to rollers while unscrewing factory parts or adding machined parts. |

(E) remove base |

instrument assembly |

Motorized stage

|

|

(F) Z-axis motor parts

includes Z-606 motorized actuator, Newport micrometer mount, Motor Split Bushing, and Z-axis Limit Nut |

(F) Z-axis motor parts |

instrument assembly |

Motorized stage

|

|

(G) Z-axis motor assembled

tighten clamp around motor and bushing |

(G) Z-axis motor assembled |

instrument assembly |

Motorized stage

|

|

(H) Z-axis Limit Sensor and Left-Handed Stage Gizmo

Vector wirewrap terminals soldered onto Z-limit Board are here longer than allowed. They will be clipped shorter before assembly. |

(H) Z-axis Limit Sensor and Left-Handed Stage Gizmo |

instrument assembly |

Motorized stage

|

|

(I) Z-axis Limit Sensor attached to Left-Handed Stage Gizmo

Vector wirewrap terminals soldered onto Z-limit Board are here longer than allowed. They will be clipped shorter before assembly. |

(I) Z-axis Limit Sensor attached to Left-Handed Stage Gizmo |

instrument assembly |

Motorized stage

|

|

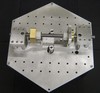

(J1) XYZ-Stage, StageBracket, StageSpreaderPlate, Z-axisMotor

Also attach 2 Chamber Legs to stage Spreader Plate with 8-32 x 3/4" cap screws |

(J1) XYZ-Stage, StageBracket, StageSpreaderPlate, Z-axisMotor |

instrument assembly |

Motorized stage

|

|

(J2) Close-up of vector wirewrap terminals in the assembly

The vector wirewrap terminals are cut to proper length and bent to desired angle to limit motor movement in z-axis. |

(J2) Close-up of vector wirewrap terminals in the assembly |

instrument assembly |

Motorized stage

|

|

(K) Motorized stage assembly (missing X and Y motors)

Also attach 2 Motor Clamps with 4-40 x 3/8" cap screws. |

(K) Motorized stage assembly (missing X and Y motors) |

instrument assembly |

Motorized stage

|

|

(L) Motorized stage assembly (with all motors)

|

(L) Motorized stage assembly (with all motors) |

instrument assembly |

Motorized stage

|

|

waveplate wrench

pins engage holes on edge of waveplate mount |

waveplate wrench |

Tools |

|

|

improved fluidics tray

|

improved fluidics tray |

Fluidics |

fluidics tray

|

|

improved pinch clamp

|

improved pinch clamp |

Fluidics |

fluidics tray

|

|

bottle holder

|

bottle holder |

Fluidics |

fluidics tray

|

|

fluidics tray assembly

Includes plastic hexagon, pinch clamp, 2 bottle holders |

fluidics tray assembly |

Fluidics |

fluidics tray

|

|

Pinch Clamp

Pinch clamp contains:

Pinch Clamp Frame,

Adjustment Screw,

Adjustment screw Nut,

Presser Foot,

Rubber Band |

Pinch Clamp |

instrument assembly |

fluidics tray

|

|

Laser Power Supply Board

side that faces away from front panel |

Laser Power Supply Board |

boards |

Laser Power Supply

|

|

panel plus board

|

panel plus board |

instrument assembly |

Laser Power Supply

|

|

Diode Driver Board Modified

Thorlabs IP 500 diode driver modified by soldering in wire harness. Remove trim pot "P/I ADJ" and solder 3 wires into holes.

Requires careful work with a "solder sucker".

The board is connected to a socket 16 through 12" ribbon cable. |

Diode Driver Board Modified |

boards |

Laser Power Supply

|

|

a) Laser power supply

|

a) Laser power supply |

instrument assembly |

Laser Power Supply

|

|

Back view

|

Back view |

instrument assembly |

Laser Power Supply

|

|

Front panel

|

Front panel |

instrument assembly |

Laser Power Supply

|

|

Front view of power supply wiring

|

Front view of power supply wiring |

instrument assembly |

Laser Power Supply

|

|

Over the front

|

Over the front |

instrument assembly |

Laser Power Supply

|

|

panel back side

|

panel back side |

instrument assembly |

Laser Power Supply

|

|

wires to laser

|

wires to laser |

instrument assembly |

Laser Power Supply

|

|

Wiring harness inside power supply

Red = +5 V,

Black = ground,

Yellow = -5 V |

Wiring harness inside power supply |

instrument assembly |

Laser Power Supply

|

|

Jumpers

Jumper (J5) from panel board to panel meter |

Jumpers |

|

Laser Power Supply

|

|

Z) fiber wiggler

Fiber Wiggler is attached inside " Mirror Mount 3-Screw" Thorlabs KS-05 |

Z) fiber wiggler |

instrument assembly |

wiggler mount

|

|

A) parts to mount

|

A) parts to mount |

instrument assembly |

Optical rail and objective sliding mount

|

|

B) attach stage left

|

B) attach stage left |

instrument assembly |

Optical rail and objective sliding mount

|

|

C) attach stage right

|

C) attach stage right |

instrument assembly |

Optical rail and objective sliding mount

|

|

D) test the bracket

|

D) test the bracket |

instrument assembly |

Optical rail and objective sliding mount

|

|

E) attach the gear

Must be a close sliding fit. Clean shaft and gear with alcohol to remove oil.. Apply 5-min epoxy to shaft and gear and slide together. |

E) attach the gear |

instrument assembly |

Optical rail and objective sliding mount

|

|

F) assemble worm gear

|

F) assemble worm gear |

instrument assembly |

Optical rail and objective sliding mount

|

|

G) thread inserts

|

G) thread inserts |

instrument assembly |

Optical rail and objective sliding mount

|

|

H) insert screwed in

|

H) insert screwed in |

instrument assembly |

Optical rail and objective sliding mount

|

|

I) attach rail

|

I) attach rail |

instrument assembly |

Optical rail and objective sliding mount

|

|

J) objecive holder on rail

|

J) objecive holder on rail |

instrument assembly |

Optical rail and objective sliding mount

|

|

mechanical alignment test

3/8" rod should slide through prism box front holes and objective mount bushings |

mechanical alignment test |

Tools |

mechanical alignment set

|

|

Pipette puller

|

Pipette puller |

Tools |

Pipette Puller

|

|

pipette puller 2

|

pipette puller 2 |

Tools |

Pipette Puller

|

|

Instrument head open

|

Instrument head open |

instrument assembly |

instrument Head

|

|

miniTweezers instrument head

instrument head of dual-beam counter-propagating optical trap. |

miniTweezers instrument head |

instrument assembly |

instrument Head

|

|

A) Mechanical parts only

|

A) Mechanical parts only |

instrument assembly |

force detector

|

|

B) Mechanical parts assembled

|

B) Mechanical parts assembled |

instrument assembly |

force detector

|

|

C) Circuit boards and cables

This is a picture of the detector with the DL-10 detector with its window removed and soldered in place. |

C) Circuit boards and cables |

instrument assembly |

force detector

|

|

D) PSD Holder with 2 detector boards

Shown is the DL-10 detector with window removed. To learn how to remove it, see "How to: Remove the window cover from the DL-10 detector" under Documents. Make sure to solder the detector in the proper orientation in accordance with the picture. |

D) PSD Holder with 2 detector boards |

instrument assembly |

force detector

|

|

E) PSD Holder with assembled boards

|

E) PSD Holder with assembled boards |

instrument assembly |

force detector

|

|

F) Detector assembly with beamsplitter cube

Non-polarizing beamsplitter cube inserted with slope toward PSD detector so reflected light goes to PSD and transmitted light goes to Iris detector (PIN 10-DI). Cube held in place with plastic-tip set screw. Get set screws from Thorlabs KM05 mirror mount where they will not be used. |

F) Detector assembly with beamsplitter cube |

instrument assembly |

force detector

|

|

G) Cube in place

Looking from this view one sees PSD and Iris detectors superposed due to half-silvered mirror. |

G) Cube in place |

instrument assembly |

force detector

|

|

H) Piece of tape blocks stray light

|

H) Piece of tape blocks stray light |

instrument assembly |

force detector

|

|

I) Complete detector assy on bracket

|

I) Complete detector assy on bracket |

instrument assembly |

force detector

|

|

J) Bullseye filter setup

One detector needs one bullseye filter, one disk and a cut piece of tape with 0.5" diameter hole |

J) Bullseye filter setup |

instrument assembly |

force detector

|

|

K) Insert the bullseye filter centered on the detector and then put the disk over

|

K) Insert the bullseye filter centered on the detector and then put the disk over |

instrument assembly |

force detector

|

|

M) Seal the detector with tape and trim off the border

|

M) Seal the detector with tape and trim off the border |

instrument assembly |

force detector

|

|

(H) Glue the front surface to the metal parts

Use superglue |

(H) Glue the front surface to the metal parts |

instrument assembly |

position detector lower periscope

|

|

(I) Remove blue backing from front-surface mirrors

|

(I) Remove blue backing from front-surface mirrors |

instrument assembly |

position detector lower periscope

|

|

(J) Attach plastic lenses to sliders.

Convex lens side faces in, flat side out. Use very little super glue and avoid getting glue on lens face. Replace lens if that happens. |

(J) Attach plastic lenses to sliders. |

instrument assembly |

position detector lower periscope

|