| | Picture | Title | Category | Assembly |

|---|

|

A) apply epoxy

about 2 uL of UV-set epoxy spread on flat bevel of pickoff tube |

A) apply epoxy |

instrument assembly |

position detector lower periscope

|

|

B) position film

raise pickof tube until it stretches the film |

B) position film |

instrument assembly |

position detector lower periscope

|

|

C) cure epoxy

5 minutes at high power in UV crosslinking chamber |

C) cure epoxy |

instrument assembly |

position detector lower periscope

|

|

D) cut film

outside of tube with scalpel blade |

D) cut film |

instrument assembly |

position detector lower periscope

|

|

E) trim film

file away excess film and epoxy from edge of pickoff tube |

E) trim film |

instrument assembly |

position detector lower periscope

|

|

G) finished pickoff tube

with attached pellicle |

G) finished pickoff tube |

instrument assembly |

position detector lower periscope

|

|

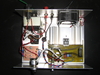

filter slider

assembled filter slider shown before cutting extra cable and before glueing galss filters. |

filter slider |

instrument assembly |

filter slider

|

|

filter slider parts

components of filter slider |

filter slider parts |

instrument assembly |

filter slider

|

|

A) Prism Box Parts

|

A) Prism Box Parts |

instrument assembly |

Prism Box

|

|

B) Countersink holes

Countersink holes for 2-56 flat head screws. The metal is too thin for full depth countersink. Just stop when you start to enlarge the clearance hole out the other side. The thicker Prism Box Lid will accept a full depth countersink. The remaining depth is tapped 2-56 so you can screw in a flat-headed screw pointing out ofn the box and the screw head will not rise above the inside surface of the box and scratch the glass prisms. |

B) Countersink holes |

instrument assembly |

Prism Box

|

|

C) Attach Front, Back

test that parts fit together |

C) Attach Front, Back |

instrument assembly |

Prism Box

|

|

D) Place PBS cubes and RA prisms

|

D) Place PBS cubes and RA prisms |

instrument assembly |

Prism Box

|

|

E) Place Spacer Cubes

|

E) Place Spacer Cubes |

instrument assembly |

Prism Box

|

|

F) Place spacer wedges

|

F) Place spacer wedges |

instrument assembly |

Prism Box

|

|

G) Attach Cover

|

G) Attach Cover |

instrument assembly |

Prism Box

|

|

I) ND filter taped over the relay lens.

Prism_Box_Frame version 2 will have room for ND filter and 75mm lens both inside hole. Lay filter directly on pbs cube. Then lay flat side of lens directly on filter. Then screw in retainer ring. |

I) ND filter taped over the relay lens. |

instrument assembly |

Prism Box

|

|

H) Prism box with lenses

The numbers show the focal lengths of the lenses (in millimeters). |

H) Prism box with lenses |

instrument assembly |

Prism Box

|

|

Position detector back

Use heat shrink tubing to surround the connections to the temperature sensor.

Order of the wires in the 8-pos connector are as follows. Starting from the first position which is marked with a triangle on the connector, the top row is: blue, black, green, and bare wires. The second row is: brown, white, and red wires. |

Position detector back |

instrument assembly |

position detector

|

|

Position detector front

|

Position detector front |

instrument assembly |

position detector

|

|

Position detector with filter detector on

|

Position detector with filter detector on |

instrument assembly |

position detector

|

|

Position with filter flipper

|

Position with filter flipper |

instrument assembly |

position detector

|

|

mini suspenders

suspenders shown on top of instrument, ready for shipping |

mini suspenders |

instrument assembly |

mini suspenders

|

|

(7) Attach detector cables

Plug detector cables into 8-pin headers on Preamp Boards. Position connector with red wire and blank position on top. Be carefull not to plug it upside down or offset right/left by 1 pin. Such a mistake won't damage anything, but it won't work that way. |

(7) Attach detector cables |

boards |

Analog to Digital Converter Board

Controller Board Stack

|

|

ADC Mother board

Install 2 jumpers:

(1) from EOC (End Of Conversion) to ribbon wire 17

(2) from CS (Chip Select) to ribbon wire 15 |

ADC Mother board |

boards |

Analog to Digital Converter Board

|

|

ADC board with piggyback preamplifier boards

|

ADC board with piggyback preamplifier boards |

boards |

Analog to Digital Converter Board

|

|

Rear side of the ADC board with three capacitors highlighted

|

Rear side of the ADC board with three capacitors highlighted |

instrument assembly |

Analog to Digital Converter Board

|

|

Zoom-in view of the capacitors

Showing three chip capacitor Yageo CC0805KRX7R8BB104 |

Zoom-in view of the capacitors |

instrument assembly |

Analog to Digital Converter Board

|

|

bare skeleton

|

bare skeleton |

instrument assembly |

Framework

|

|

cable clamps and wiring harnesses

|

cable clamps and wiring harnesses |

instrument assembly |

Framework

|

|

Mark hole position on hex spacers

Choose 4 hex spacers across ends of optical path (not front or back where cables come out). Hold crossbar level with its top edge at the same height as the Sided-Panel mounting holes. Mark Hex Spacers with pencil at center of slot in Crossbar Bracket. Remove spacers and drill/tap 4 holes to accept 6-32 screws. |

Mark hole position on hex spacers |

instrument assembly |

Framework

|

|

board back side

|

board back side |

boards |

laser power supply circuit board

|

|

board front side

|

board front side |

boards |

laser power supply circuit board

|

|

Push button Modified

Bend tabs and solder wires that will feed through holes in PC board |

Push button Modified |

boards |

laser power supply circuit board

|

|

laser assemblies underneath the hexagonal top

|

laser assemblies underneath the hexagonal top |

instrument assembly |

Instrument Lid with Lasers

|

|

(A) Lower optical train showing prism box, spacers, and lower periscope.

Drill a 3/16" hole in two of the Prism Box Standoff Spacers so that an allen wrench can be inserted through the holes to tighten the screws which lock the Light Lever Pickoff Tubes in place. |

(A) Lower optical train showing prism box, spacers, and lower periscope. |

instrument assembly |

Lower optical train

|

|

(B) Remove the position detector lower periscope.

Note that the Light-Lever-Standoff-Spacer is asymmetric and that it is installed so the 5/16" hole for the periscope is closer to the Prism Box than to the Optical Rail.

This section will be covered with tape to protect the optics from dirt and splashed buffer. |

(B) Remove the position detector lower periscope. |

instrument assembly |

Lower optical train

|

|

(C) Wrap with 1" black tape (Thorlabs T137-1.0) and cut two holes with scalpel (see description).

Larger hole is for the lower periscope, and the smaller hole is for the wrench to access the screw in the pick-off assembly for adjustment. |

(C) Wrap with 1" black tape (Thorlabs T137-1.0) and cut two holes with scalpel (see description). |

instrument assembly |

Lower optical train

|

|

(D) Reinstall position detector lower periscope.

|

(D) Reinstall position detector lower periscope. |

instrument assembly |

Lower optical train

|

|

detector boards

|

detector boards |

boards |

|

|

motor limit board

Part of Detector Board set has been cut ouy |

motor limit board |

boards |

|

|

winch assembled

|

winch assembled |

Tools |

Winch

|

|

winch pieces

|

winch pieces |

Tools |

Winch

|

|

Pulley and bungee cord

Pulley attached to pipe on ceiling. Cable from winch feeds through pulley and pulls bungee cord. |

Pulley and bungee cord |

Tools |

Winch

|

|

Winch

|

Winch |

Tools |

Winch

|

|

Magnetic Lens Mount

magnetic ring is held by 3 rare-earth magnets which are glued into depressions (holes marked "F") in the Hexagon Base |

Magnetic Lens Mount |

instrument assembly |

CCD camera assembly

|

|

Pipette puller power supply inside view

|

Pipette puller power supply inside view |

Tools |

Puller Power Supply

|

|

Coverslip jig

Glass coverslips are placed into slots and rest against dowel pins on left side |

Coverslip jig |

Tools |

Coverslip jig

|

|

coverslip jig 2

|

coverslip jig 2 |

Tools |

Coverslip jig

|

|

Nesco film roller

|

Nesco film roller |

Tools |

nescofilm roller

|

|

improved fluidics

see Document "How to Improve Fluidics" |

improved fluidics |

Fluidics |

Fluidics set

|

|

Fluidics set

|

Fluidics set |

Fluidics |

Fluidics set

|

|

(A) Making holes in nylon set screws

Drill holes into the nylon socket set screw using a #45 drill bit (0.082") while holding them in place with a post with 8-32 threading. Notice that one end will be narrower than the other after drilling. |

(A) Making holes in nylon set screws |

Fluidics |

Silicone Tube Adapter

|

|

(B) Threading silicone tubing through nylon socket set screws

Cut end of Tygon silicone tubing with a sharp edge (ex. razor) to thread it through the holed socket set screws with 1-inch spacing, aligned in the same direction. Cut evenly with 2-mm spacing in front of the narrower end of the screw. |

(B) Threading silicone tubing through nylon socket set screws |

Fluidics |

Silicone Tube Adapter

|

|

(C) Applying Silicone tubing adapter

Screw the silicone tubing adapter into the chamber holder by twisting the silicone tubing until it buckles. |

(C) Applying Silicone tubing adapter |

Fluidics |

Silicone Tube Adapter

|

|

Dowel pins made from 1/8" Brass tube

Use same brass tube as in wiggler, cut to 1/2" length |

Dowel pins made from 1/8" Brass tube |

instrument assembly |

|

|

Press pins into holes using guide to keep them straight

Metal guide made from 1/4" thick scrap aluminum. Drill with #30 drill |

Press pins into holes using guide to keep them straight |

instrument assembly |

|

|

Prism Box Machined Pieces

aluminum pieces are the same on RH and LH prism box |

Prism Box Machined Pieces |

|

|

|

Preamp Board bottom

|

Preamp Board bottom |

boards |

Preamp board

|

|

Preamp Board side

|

Preamp Board side |

boards |

Preamp board

|

|

Preamp Board top

|

Preamp Board top |

boards |

Preamp board

|

|

Motor Cable Clamp

where motor cable harness enters instrument head |

Motor Cable Clamp |

instrument assembly |

motor cable harness

|

|

Motor cable harness

|

Motor cable harness |

instrument assembly |

motor cable harness

|

|

Main control board

|

Main control board |

boards |

main control board

|

|

Rear side of the main control board

Three capacitors are Panasonic ECJ-3VB1E334K |

Rear side of the main control board |

instrument assembly |

main control board

|

|

puller filament holder

|

puller filament holder |

Tools |

puller Head

|

|

puller head complete

|

puller head complete |

Tools |

puller Head

|

|

Pipette puller head

|

Pipette puller head |

Tools |

puller Head

|

|

Pipette puller head

|

Pipette puller head |

Tools |

puller Head

|

|

puller fixer clamp

6-32 socket-head screw, plastic thumb-screw knob, fixer clamp. Round brass nut ring is threaded onto screw and glued in place with epoxy so that unscrewing knob will pull fixer clamp away from Slider or Top piece. |

puller fixer clamp |

Tools |

puller Head

|

|

Motor control board

|

Motor control board |

boards |

Motor control board

|

|

B) Laser Mount wiring

Wire connections to Laser Mount PC Board and on DB-9 connector. On the connector wire pins as follows:

Pin1=brown

Pin2=red

Pin3=orange

Pin4=yellow

Pin5=green

Pin6=blue (same end as pin1)

Pin7=violet

Pin8=black

Pin9=white (same end as pin5) |

B) Laser Mount wiring |

instrument assembly |

Laser assembly

|

|

C) Diode laser (Lumics) and laser base

Laser, base and circuit board with wires attached

Schottky diode protects Laser diode from static |

C) Diode laser (Lumics) and laser base |

instrument assembly |

Laser assembly

|

|

A) Base with circuit board

|

A) Base with circuit board |

instrument assembly |

Laser assembly

|

|

D) Unwind the optical fibre from the box

|

D) Unwind the optical fibre from the box |

instrument assembly |

Laser assembly

|

|

E) Fix the laser into the laser base

|

E) Fix the laser into the laser base |

instrument assembly |

Laser assembly

|

|

F) Wind the optical fibre inside the laser base clockwise

|

F) Wind the optical fibre inside the laser base clockwise |

instrument assembly |

Laser assembly

|

|

G) Feed the FC termination inside

FC termination goes through the hole on the laser base front, then it is fed through the feedthru plate into the adapter from ThorLabs with cap. |

G) Feed the FC termination inside |

instrument assembly |

Laser assembly

|

|

H) Fix the feedthru plate

|

H) Fix the feedthru plate |

instrument assembly |

Laser assembly

|

|

I) Place foam inside to keep the optical fibre in place

|

I) Place foam inside to keep the optical fibre in place |

instrument assembly |

Laser assembly

|

|

J) Ground soldering iron to the laser base

|

J) Ground soldering iron to the laser base |

instrument assembly |

Laser assembly

|

|

K) Solder the laser to the base

|

K) Solder the laser to the base |

instrument assembly |

Laser assembly

|

|

L) Cover the laser base and label with serial number

|

L) Cover the laser base and label with serial number |

instrument assembly |

Laser assembly

|

|

optical_layout

|

optical_layout |

instrument assembly |

|